Mobile Stage

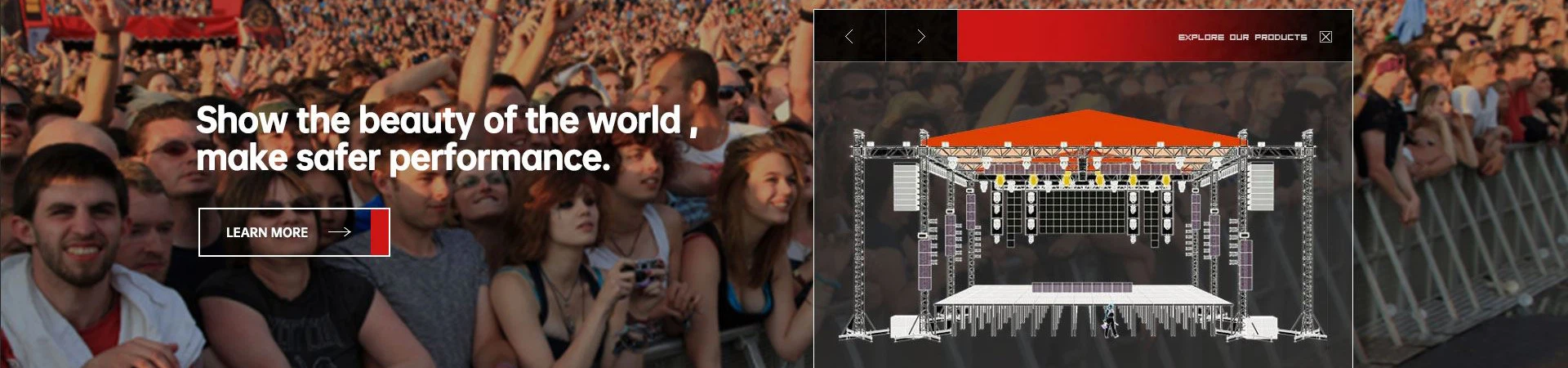

1.Introduction The Outdoor Mobile Stage is a portable and versatile platform designed for artists to deliver exceptional performances. With its integrated wheels, it offers ease of installation and transportation, making it the ideal choice for any event. Complemented with trusses and lights,...

Description

1.Introduction

The Outdoor Mobile Stage is a portable and versatile platform designed for artists to deliver exceptional performances. With its integrated wheels, it offers ease of installation and transportation, making it the ideal choice for any event. Complemented with trusses and lights, this stage provides the perfect setting to showcase talent and create memorable experiences.

2.Truss specifications

|

Item Name |

mobile stage |

|

Material |

Aluminum alloy 6061-T6/Plywood/PVC/Acrylic/Glass |

|

Feature |

Height adjustable, easy install |

|

Size |

2m*1m,1m*1m,1.22*2.44m,1.22*1.22m ect |

|

Leg main tube |

50x3mm |

|

Brace tube |

50x2mm |

|

Frame size |

78x43x3mm |

|

Certificate |

ISO, CE, TUV, SGS |

|

Application |

School events like parties, concerts, exhibitions, and catwalk fashion shows are always a great opportunity for students to showcase their talents and creativity. Whether it's a vibrant concert filled with music and dance or an art exhibition showcasing the students' artistic abilities, these events bring the school community together. The catwalk fashion show is a highlight where students can flaunt their fashion sense and design skills. These events not only provide entertainment but also foster a sense of unity and pride within the school. It's incredible to witness the enthusiasm and energy that students bring to these events, making them memorable experiences for everyone involved. church,wedding,etc. |

|

Delivery Time |

Depends on order qty |

|

Dimension |

Max. Loading |

Max. Height |

Min. Height |

|

1m*1m |

1000kg |

1200mm |

200mm |

|

1.22m*1.22m |

1000kg |

1200mm |

200mm |

|

1m*2m |

900kg |

1200mm |

200mm |

|

1.22*2.44m |

900kg |

1200mm |

200mm |

3.Production Process

The typical procedure for manufacturing an aluminum mobile stage usually includes the subsequent processes:

1. Aluminum Selection: Initially, the appropriate grade of aluminum is chosen for the production of the mobile stage. Factors such as strength, weight, and durability are taken into consideration during the selection process.

2. Metal Cutting: The selected aluminum sheets are then cut into the required sizes and shapes using specialized cutting tools and techniques. This stage aims to shape the components that will make up the mobile stage.

3. Welding and Joining: The cut aluminum components are assembled and welded together to form the framework of the mobile stage. This welding process requires skilled technicians who ensure the joints are secure and sturdy.

4. Surface Treatment: After the assembly, the surfaces of the aluminum components are treated to enhance their appearance and protect them from corrosion. This may involve techniques such as cleaning, sanding, polishing, and applying protective coatings.

5. Installation of Accessories: Various accessories, such as handrails, stairs, and panels, are installed onto the aluminum framework to complete the structure of the mobile stage. These accessories are carefully positioned and securely attached to ensure the overall stability and functionality of the stage.

6. Quality Control: Throughout the production process, strict quality control measures are implemented to ensure that the mobile stage meets the required standards. This includes inspections, testing, and adherence to safety regulations.

7. Packaging and Shipping: Once the aluminum mobile stage passes the quality control checks, it is packaged appropriately to protect it during transportation. The stage is then shipped to its destination, ready to be assembled and used for various events and performances.

To begin creating a mobile stage, the design process must be carefully considered. This involves determining key factors such as the stage's size, weight, and weight-bearing capacity. Other important details such as stairs, railings, and lighting will also be incorporated into the design. A thorough and well-executed plan will ensure that the final product meets the needs of its intended use and is safe and functional.

When the design for a product has been finalized, the next step is to carefully choose the materials that will be used. One popular option is aluminum, which offers a perfect balance between strength, durability, and weight. This material is widely chosen due to its dependable and sturdy qualities, making it an ideal choice for many different applications. Proper selection of materials can greatly enhance the overall quality and longevity of the end product, while also helping to control costs.

Cutting and shaping play a crucial role in the production of mobile stages. The aluminum components undergo a precise process where they are cut and shaped to match the specific design and dimensions required. This task is accomplished by utilizing specialized tools including saws, drills, and routers. Each tool serves a specific purpose in achieving the desired shape and form of the components. By applying these cutting and shaping techniques, the mobile stage manufacturers are able to create highly customized and precisely engineered structures.

During the assembly process, the aluminum components are joined together using either welding or bolting techniques. It is crucial to pay close attention to detail at this stage in order to guarantee the strength and security of the joints.

Upon completion of the assembly of the mobile stage, it undergoes a process known as finishing. This step is crucial as it provides a protective layer to safeguard the stage from corrosion and other forms of damage. Various methods are employed in this process, such as painting, powder coating, or anodizing the aluminum surface. The chosen method depends on the desired outcome and the specific requirements of the stage. By applying this finishing touch, the stage is prepared to withstand the rigors of use and maintain its quality and appearance over time.

6. Quality control: The finished mobile stage is then thoroughly inspected to ensure that it meets the necessary safety standards and is ready for use. This includes load testing, stability testing, and other safety checks.

7. Packaging and shipping: Finally, the mobile stage is packaged and shipped to the customer. The packaging will be designed to protect the mobile stage during transportation and ensure that it arrives in good condition.

Overall, the production process for an aluminum mobile stage involves careful planning, precision cutting and shaping, expert assembly, thorough quality control, and safe packaging and shipping.

4.Product Application

Safe Mobile Stages produced by Shizhan Group are widely used for performances.,it is also widely used for concerts.,so far we have the unit size :1.22x1.22m/1x1m/1x2m/1.22x2.44m or customized, and the height range from 0.4-0.6m/0.6-1.0m/0.8-1.3m/1-1.5m

5.FAQ

1: What is your advantage

We are a 16 years truss and stage factory,our products have passed German TUV certificate

2: How do i know your quality? Do you support sample order?

Our products has obtained TUV/SGS/CE/ISO9001 Certificates in the international market,which proves that our products’s Excellent quality.

We can also offer samples for customer to do the quality checking before placing the batch order.

Hot Tags: mobile stage, China mobile stage manufacturers, suppliers, factory

Send Inquiry

You Might Also Like